The concrete wall facing Airport Way South fades into the surrounding SODO neighborhood so easily that some people might miss what’s behind it. The best hints: A silver water fountain – shaped a bit like a pretzel – and the words “Seattle Public Utilities” emblazoned in a corner of an outside office area wall.

Behind the main concrete wall – among various SPU teams in Water and Shared Services, Meter Reading, Safety and Security, Emergency Management, Community Affairs, and the Operations Response Center – is the warehouse at the Operations Control Center (OCC): Housed within the OCC, which spans nearly a city block, the warehouse contains about 12,000 unique pieces of equipment, and provides Utility crews with more than 200 years of combined staff experience and knowledge.

SPU crews need this equipment, materials, and gear for construction, maintenance, repairs, and emergencies – and to ensure the utilities that Seattle’s more than 749,200 residents and the region’s 1.5 million drinking water customers rely on work properly at all hours of the day. This warehouse is just one of the many critical locations and investments that enables SPU to fulfill its mission.

“We have quality control for everything that comes through the door to give crews in the field assurance,” said Willie Manning, the facility’s Chief Warehouser who started working at the Utility/Water Department a year before SPU formed in 1997. “My friends and family rely on this water and our services.”

Step into the warehouse – known as the Central Storeroom and which rivals any big-box hardware store – and look beyond the service desk’s metal security fence. What you see can boggle the mind but in a reassuring way.

On two levels, among rows and rows of stacked shelves are gloves, boots, hard hats with full or baseball cap-style brims, water connector parts known as couplings, flagging tape, brass fittings, shovels, pitchforks, and orange safety cones.

Also, in this storeroom that soars nearly 40 feet in height: Iron ducts, Vactor truck hoses, copper pipes, pipe fittings, slip and mechanical joints, security cameras, door locks, water meters, valves, gaskets, adapters, electrical parts, neon safety vests, and heavy-duty bags to haul gear.

There are iron sleeves that weigh 200 pounds per piece. Some storage shelves support about 3,000 pounds worth of equipment. Pipe and sleeve diameters span 20 and 30 inches. Outside, pipes and more equipment sit in the storage yard.

“It’s a great feeling to know we have the parts our crews need,” Manning said. “I take this work seriously.”

This warehouse near South Lander Street has even supplied the City of Seattle mayor with a shovel for ground-breaking ceremonies.

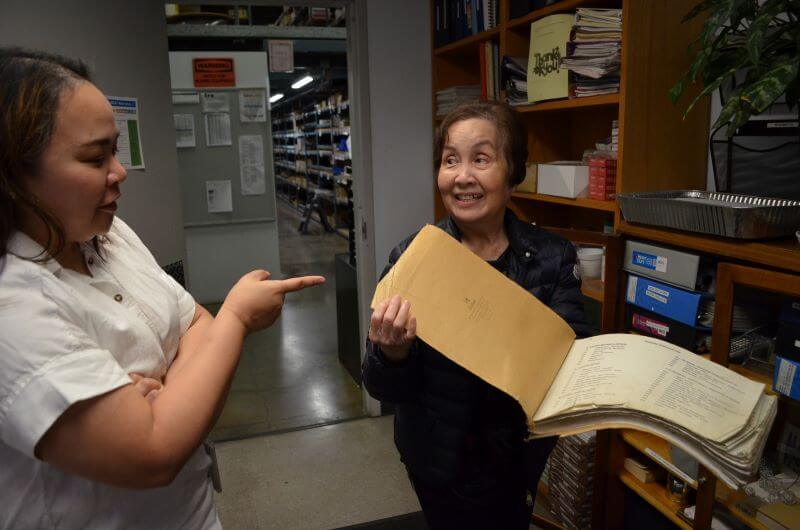

For Bolinda Partman, a Senior Warehouser who has worked at this site for more than 20 years, the job is meaningful because she engages with SPU colleagues and helps troubleshoot questions about field work.

“We help people figure out what they want,” she said. “We’re responsible for making sure things get built.”

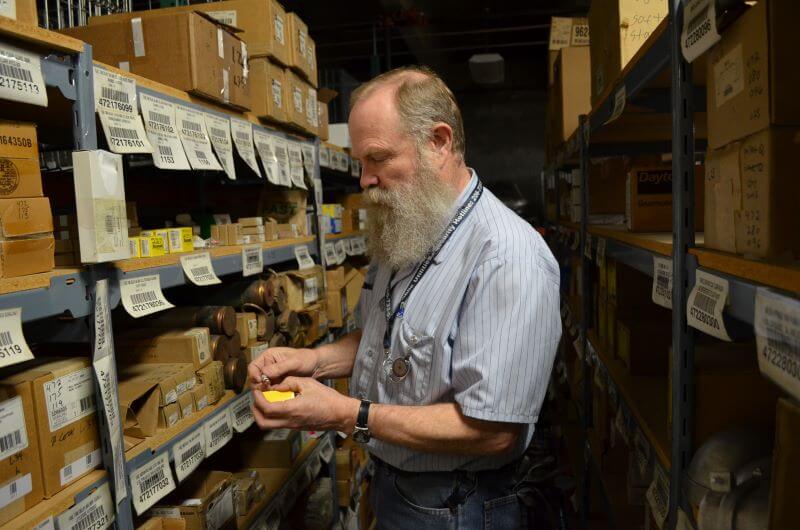

Bruce Ittner, a Senior Warehouser, paused on a recent day to calculate the combined years of experience that all SPU staff at the Central Storeroom bring to the job. His estimate: More than two centuries of experience and knowledge – easily.

This helps get to solutions faster, say, for example, when an SPU frontline worker has a question about whether an adapter or valve is the right part for the job. “We’re like the stagehands who make a play work,” Ittner said. “That’s what makes it worth doing this job.”

Manning’s day starts at 4:30 am when he arrives for equipment safety inspections with warehouse staff members. By 5 am, he and his staff are checking equipment and gear requests from SPU colleagues that arrive via Maximo, an SPU computer system. Warehouse staff recently adjusted their schedules to provide more time to prepare for customers.

By 7 am, the Central Storeroom opens for SPU employees to pick up gear and equipment. Manning and his staff also make deliveries, especially during emergencies. By 3:30 pm, the storeroom closes for the day.

“Sometimes, I have more inventory than our suppliers,” Manning said.

SPU does serve the Pacific Northwest’s most populous city. It also receives equipment requests from counterpart agencies in Snohomish County, Bellevue, Tacoma, and Portland.

Manning’s office sits next to a key part in this operation – the Material Control Office, which handles the ordering of equipment, supplies, and gear.

Central to this effort are Ann Andres, the Principal Material Controller, and her Material Control teammates, Alex Roybal and Doug Randeberg.

Andres started working for what is now SPU a year before the Utility officially began. Back then, she and Manning estimate, the Central Storeroom only had about 3,000 unique items.

“You need to have passion for what you do. You need to have procedures, and you need to learn from errors,” she said.

“She is very meticulous. She maintains internal controls. It’s a collaboration with Willie,” said Claudette Cabral Aure, Manager of the Warehouse Group of SPU’s Logistics Division.

“She’s like a sister to me. If I didn’t work here, I wouldn’t have known I’d be proud to be part of this,” said Manning, who had a retail job before working for the City of Seattle.

“It’s been rewarding to explain to my family about my work,” he added. “This helps my family and friends have greater respect for City workers.”

Manning emphasizes that teamwork is critical to all warehouse operations and acknowledges the contributions and effort of colleagues: Thanh Hua, Isaiah Johnson, and Pat Kelley (OCC warehouse receiving area); Bolinda Partman, Bruce Ittner, Bryant Cook, and Tereyll Moody (OCC warehouse front counter); Dan Bogstie, Chief Warehouser (out of class), and Kenneth Corpuz, Senior Warehouser (North Operation Center); and Tomico Lindsey, Senior Warehouser (South Operation Center).

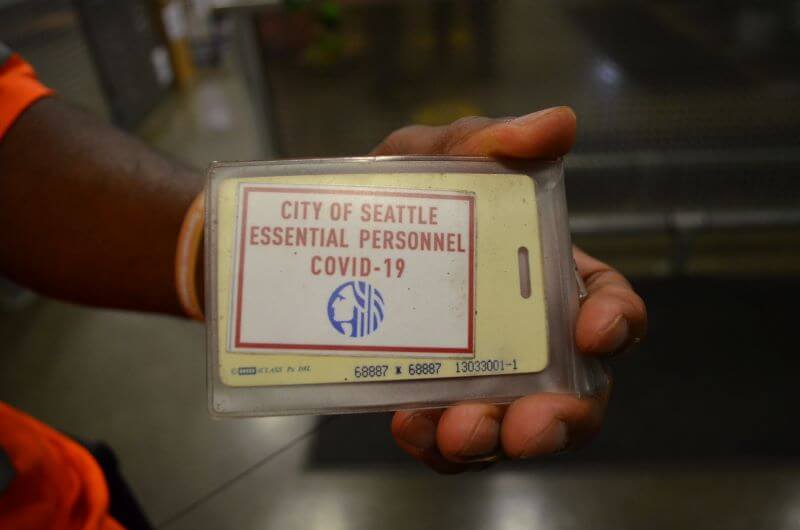

This camaraderie and commitment helped during the COVID-19 pandemic. Warehouse staff showed up because frontline SPU crews were still working in Seattle neighborhoods to ensure utilities worked properly for people, and they needed additional safety supplies to protect themselves.

“If we stayed home, I don’t know what would have happened,” Ittner said.

Even to this day, Manning keeps his red-and-blue “City of Seattle Essential Personnel COVID-19” emergency identification card in a plastic sleeve next to his SPU employee badge.

“There’s knowledge here. That’s why I’m still here,” Partman said. “We’re helping the community.”

Added Ittner: “It’s about getting the right part out at the right time.”

On this day, Hua, a Senior Warehouser, stands near the Central Storeroom’s receiving area and consults with Ittner on a question. After the conversation, Hua looks up.

“I love working here,” he said. “It’s like family. We help each other.”